Cleaning & Maintenance Solutions

Tailored cleaning, maintenance, and service solutions for cleanroom and industrial environments — designed to support processes, spatial conditions, and operational requirements.

Our Solutions

Cleaning and maintenance processes in cleanroom environments require clear structures, organized workflows, and appropriate materials. Standard products often lack the flexibility needed for these tasks.

We design cleaning and maintenance solutions individually, adapting them precisely to your processes and application areas.

Focus Areas of Our Cleaning & Maintenance Systems

Organisation Organization

Structured arrangement of cleaning and maintenance materials.

Accessibility

Quick and easy access to all required components.

Mobility

Flexible solutions for changing work locations.

Process Adaptation

Designed to align with existing cleaning and maintenance workflows.

Materials

Use of cleanroom-compatible, durable materials and surfaces.

Flexibility

Solutions tailored to different parts, formats, and application areas.

Practical Examples

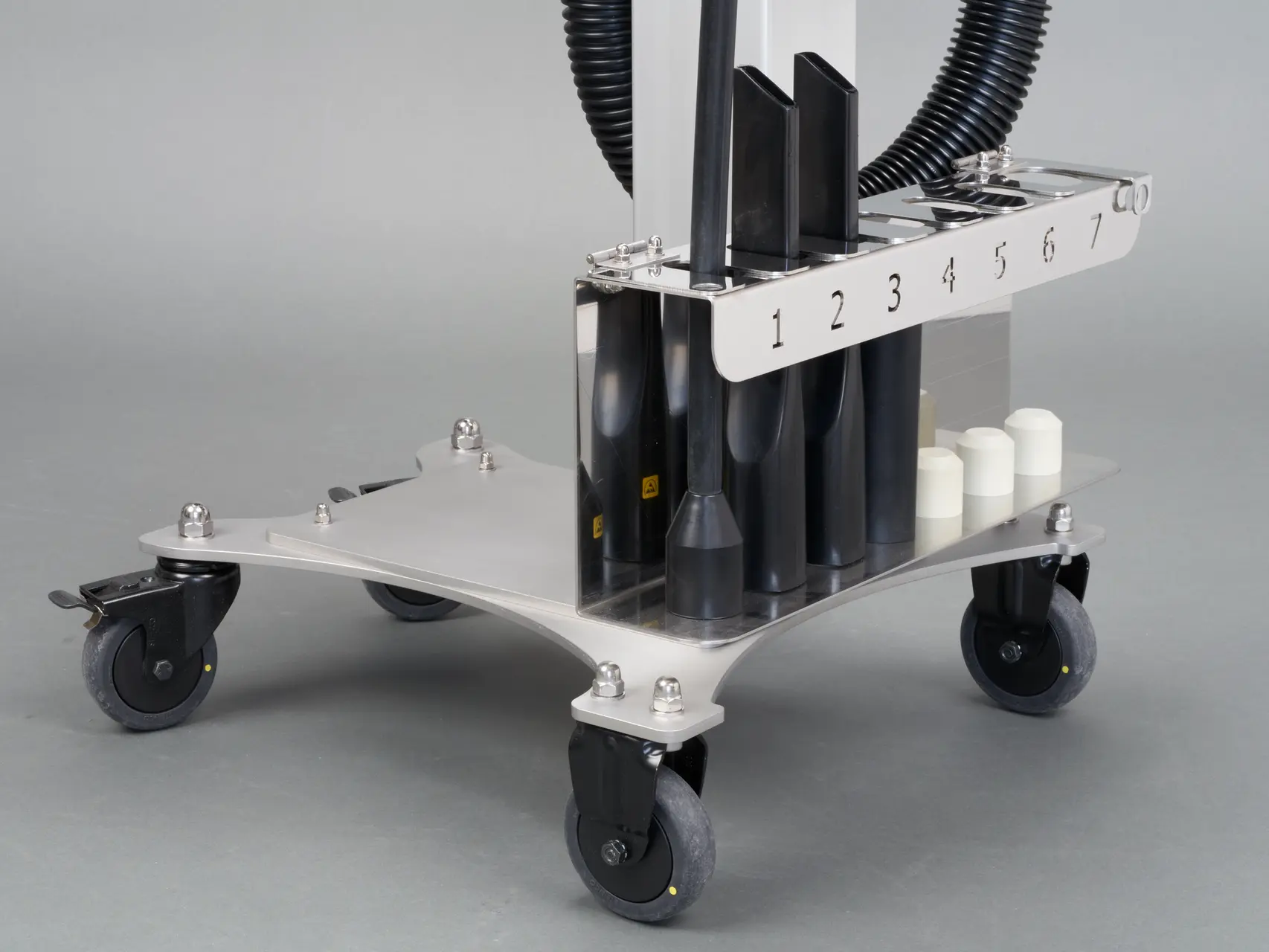

Cleaning Trolley for Maintenance & Service

The cleaning trolley supports cleaning and maintenance tasks in cleanroom and industrial environments by providing structured, mobile access to all necessary materials.

It is individually adapted to your area of application and offers organized shelves and holders for cleaning agents, wipes, gloves, and other accessories — supporting clean workflows and minimizing unnecessary movement during maintenance work.

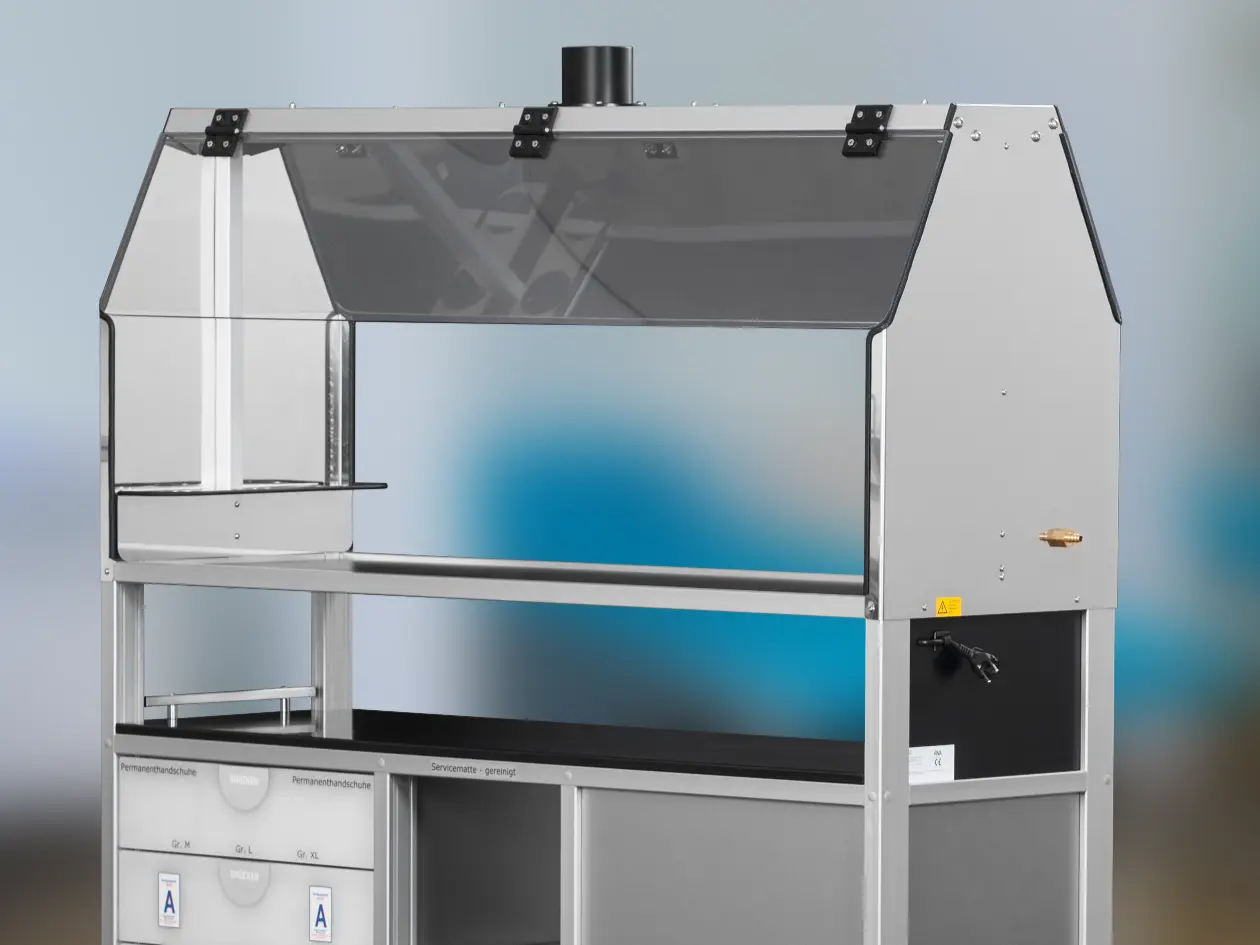

Cleaning Station

The mobile cleaning station enables flexible and structured cleaning work directly at the point of use. It is tailored to your specific cleaning processes and available space.

Custom holders for gloves, cleaning wipes, agents, and other accessories support organized workflows, and the station can be flexibly deployed in both cleanroom and production areas.

Digestors

Digestors are designed for safe handling of vapors and processes that require controlled extraction. Our digestors are individually planned and adapted to your workflows and spatial conditions.

Their cleanroom-compatible execution and clear work area support safe, clean, and controlled processes.

Hose Trolleys

Extraction units are designed for installation on tables, walls, or housings, suitable for cleanroom and industrial use. The fully enclosed stainless steel construction is designed for cleanroom environments.

An extendable vacuum hose allows precise extraction at the workplace, and operation is straightforward via push-button. ESD-compatible models support safe use in sensitive work areas.

Extraction Units

Extraction units are designed for installation on tables, walls, or housings, suitable for cleanroom and industrial use. The fully enclosed stainless steel construction is designed for cleanroom environments.

An extendable vacuum hose allows precise extraction at the workplace, and operation is straightforward via push-button. ESD-compatible models support safe use in sensitive work areas.

Mobile Maintenance Carts with IT Integration

Mobile maintenance workstations combine a full IT workstation with ample storage space for all necessary service, maintenance, and cleaning tools. They enable maintenance and service work directly at the equipment without extra travel or repeated setup, thereby supporting efficient, structured maintenance workflows in the cleanroom.

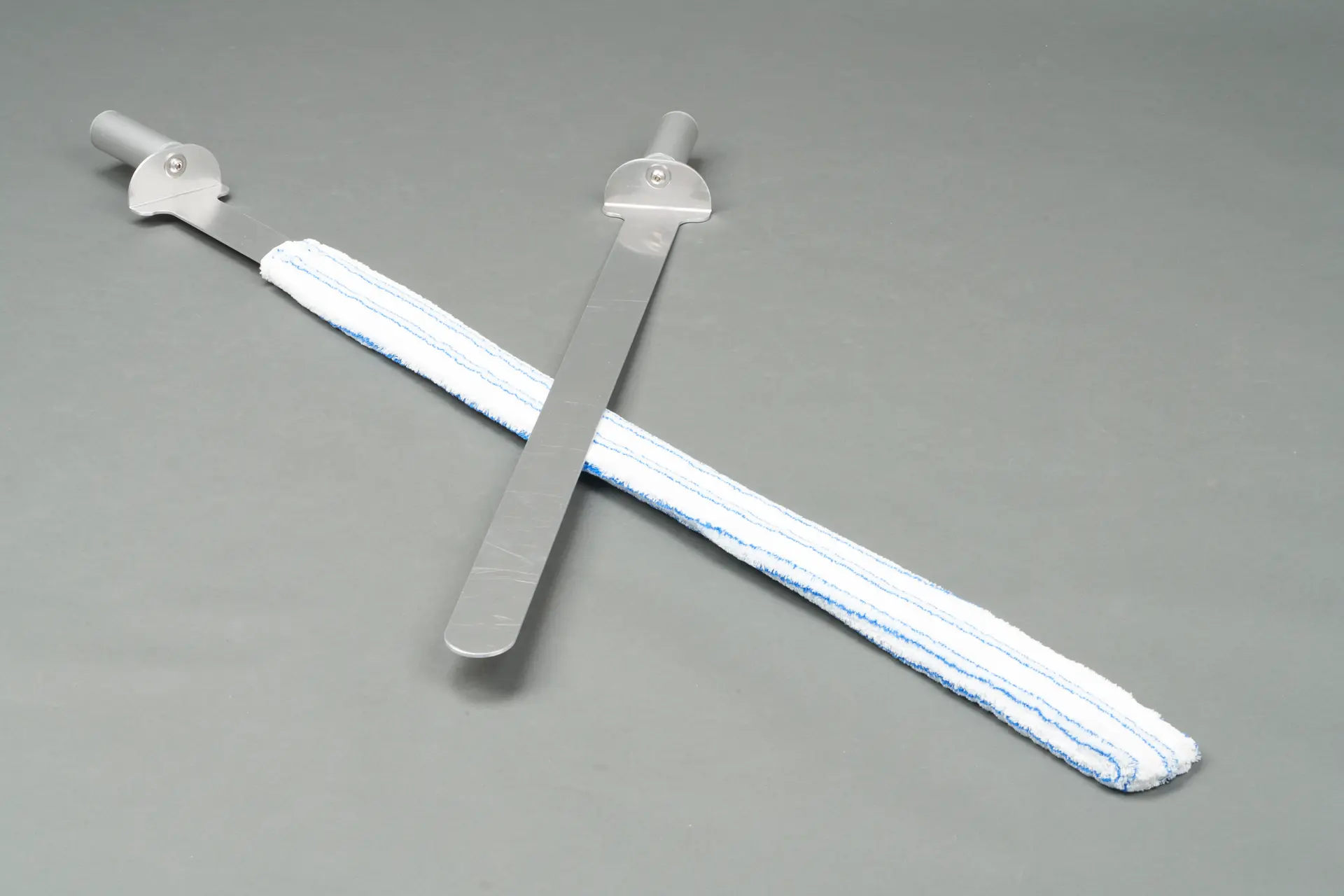

Cleaning Blade for Cleanroom & Industrial Use

The cleaning blade is designed for targeted cleaning of hard-to-reach areas on machines, systems, or components. It is tailored to the area of application, length, and cleaning requirements, ensuring controlled and efficient cleaning operations.

Its cleanroom-compatible execution supports clean workflows and is especially suitable for applications requiring precision and controlled contact.

Additional Cleaning & Maintenance Solutions

In addition to the examples shown, we develop and manufacture a wide range of solutions for cleaning and maintenance tasks in cleanroom and industrial environments. Many of these are custom builds, precisely adapted to processes, application areas, and available space.

The examples shown represent only a selection of our realized cleaning and maintenance solutions.

Why Custom Planning Matters

Every facility and cleaning process has unique requirements for organization, equipment, and space needs. Individually planned solutions support clean workflows, reduce time expenditure, and integrate optimally into existing structures.

Need a Custom Cleaning or Maintenance Solution?

We design and manufacture tailored cleaning and maintenance systems for cleanrooms and industrial environments — precisely aligned with your requirements.

What You Get From Us:

Planning & Concept Development

Manufacturing & Production

Delivery & Installation

Contact Us